General details

EDIHs involved

Challenges

Etiketa Tiskarna is a global supplier of advanced, high quality printing solutions, such as high-quality self-adhesive labels, shrink sleeves, and flexible packaging solutions, that are both R&D and technologically demanding. They supply their printed labels to the sports, textile, automotive and pharmaceutical industries.

Etiketa is looking to expand its product portfolio into printed electronics to integrate additional functionality into its products. This would open up new opportunities for applications in areas such as healthcare, energy, smart packaging and the Internet of Things (IoT). Applied CPS provided Etiketa with specialized test before invest service aimed at enhancing the integration of printed electronics within their thermal label printing processes.

Solutions

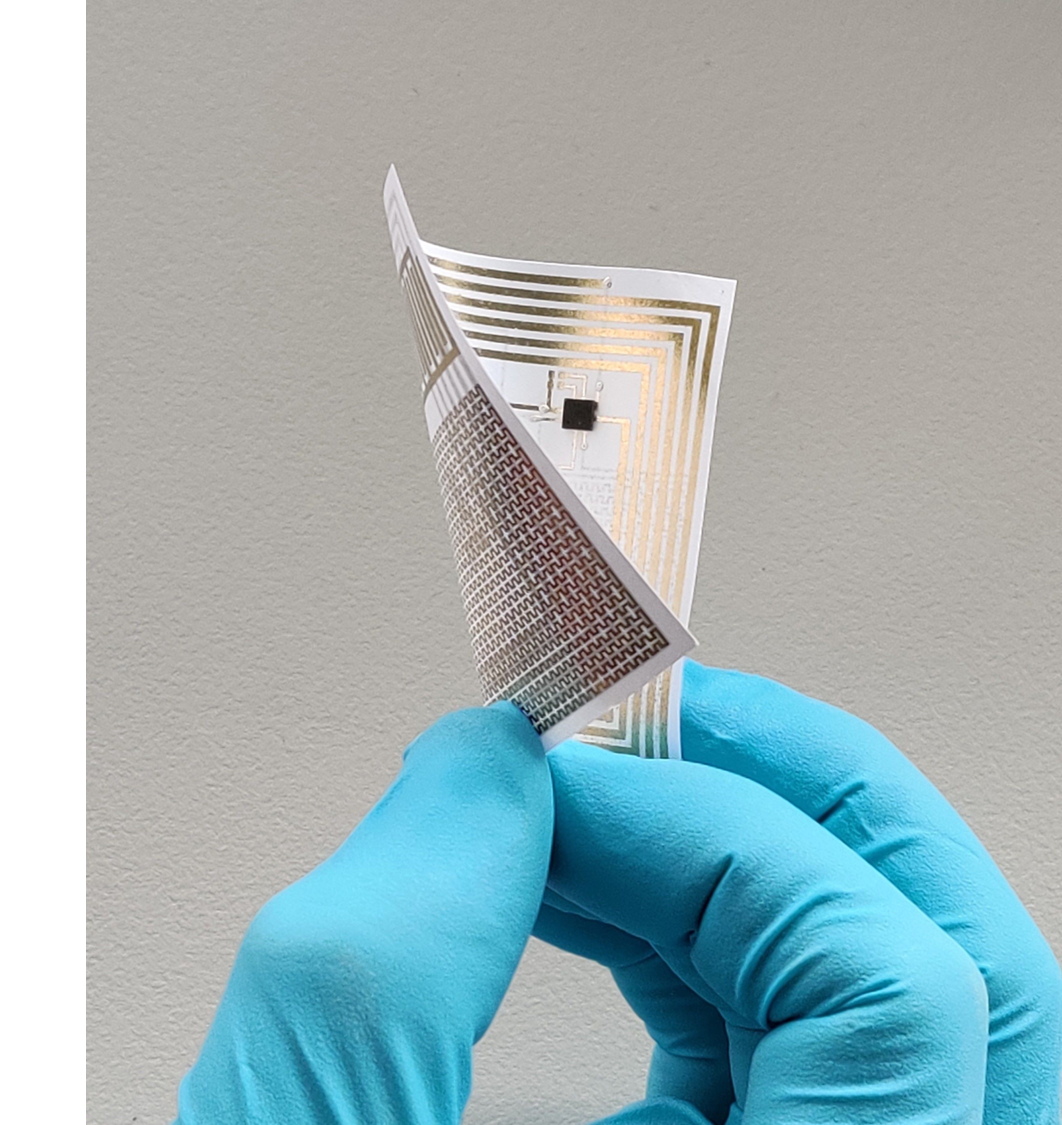

The study involved a comprehensive analysis of the fundamental suitability of using printed electronics on different layers of thermally printed labels. The research covered different layers such as the blocker layer, colour layer, etc., using different electrically conductive inks. In addition, the research looked at the exploration and application of different printing techniques, including inkjet, stencil and screen printing, to create conductive structures and designs, such as sensor electrodes.

The study involved a comprehensive analysis of the fundamental suitability of using printed electronics on different layers of thermally printed labels. The research covered different layers such as the blocker layer, colour layer, etc., using different electrically conductive inks. In addition, the research looked at the exploration and application of different printing techniques, including inkjet, stencil and screen printing, to create conductive structures and designs, such as sensor electrodes.

The research also aimed to explore the potential of producing and integrating different printed electronics manufacturing technologies with thermal label printing. The aim was to assess the compatibility of printed electronics within labels and to strategically plan subsequent research and development activities. This included an assessment of the feasibility of incorporating printed electronics into thermal label printing processes, with a view to advancing technology and innovation.

The study laid the groundwork for understanding the intersection of printed electronics and thermal label printing, and set the stage for future research efforts. By identifying key challenges and opportunities, the research set the stage for advancing this innovative field, highlighting the transformative potential of integrating printed electronics into conventional thermal label printing.

The integration of printed electronics with thermal label printing represents a significant technological advance with significant potential benefits, but it also involves significant research and development (R&D) costs which can be prohibitive for an individual company, especially smaller ones. Public funding can help offset these costs and encourage private companies to invest in innovative projects that they might otherwise avoid due to financial risk.

Results and Benefits

The service provided ETIKETA with a crucial initial understanding of the potential for integrating printed electronics into their thermal label printing processes. It provided insight into the feasibility of printing electrical structures on or within their prints and highlighted the challenges involved. In addition, the service shed light on the barriers associated with different printing technologies and the use of different inks, which were thoroughly investigated.

These insights equip ETIKETA with the foundational knowledge needed to embark on strategic planning for the integration of printed electronics into their product line. By addressing these identified challenges, ETIKETA can now explore and develop innovative solutions, paving the way for new market opportunities. This includes the potential to venture into emerging fields such as smart textiles, intelligent labels, and other advanced products that leverage printed electronics for enhanced functionality. The service has thus set the stage for ETIKETA to position itself at the forefront of technological innovation in the label printing industry, opening avenues for growth and diversification into cutting-edge markets.

The provision of this test before invest service, having as a result the development and implementation of this innovative solution, has been partially funded through public funds. Part of the total value of the service, 40k €, has been financed by the EU and the FFG through grants and subsidies, aimed at reducing the financial burden on Etiketa and encouraging the adoption of advanced digital technologies.

Etiketa, the customer, allocated part of its budget to the research and development of the integration of printed electronics into its thermal label printing process. This investment covered expenses related to materials (substrates, inks, etc. for testing printing approaches), initial prototyping, machine costs and internal project management.

The vision for a future return on investment is that by incorporating innovative printed electronics, Etiketa will be able to offer advanced label functionalities (e.g. smart labels with sensors for wearables) that will differentiate their products in the market and potentially increase sales and market share. Labels that are purely visual can be transformed into functional devices. Public funding from EDIH acts as a catalyst and enabler.

Perceived social/economic impact

Printed electronics paves the way for a wide range of applications, driving the journey toward a digital future while offering significant advantages over conventional technologies. These advantages include compatibility with a variety of substrates, enhanced environmental friendliness, and superior production speed and efficiency. As a result, printed electronics often emerge as a more economical and sustainable alternative to traditional methods.

The project has been instrumental in uncovering new areas of application, enabling these benefits to be fully exploited on a larger scale. By exploring the potential of printed electronics, the project has set the stage for broader implementation, demonstrating how this innovative technology can transform industries, drive sustainability, and enhance production processes in ways that were previously unattainable.

Measurable data

While measurable results have yet to be realised, the potential impact of integrating printed electronics into thermal label printing is significant. Etiketa is well positioned to capitalise on these advances, with significant benefits expected in terms of product innovation, economic growth, market leadership and sustainability. Continued investment and focus on research and development will be critical to achieving these long-term goals and demonstrating tangible success in the near future.

In addition, Silicon Austria Labs and Etiketa presented the results of the EDIH service entitled "ADVANCED SMART TEXTILES: INTEGRATED PRINTED SENSORS THROUGH HEAT-PRESS TRANSFERS" at the International Exhibition and Conference for Flexible, Organic and Printed Electronics (LOPEC 2024) in Germany. The LOPEC conference is the world's leading communication platform for research, knowledge and solutions in the printed electronics industry.

DMA score and results - Stage 0

Digital maturity level: 81%

Digital Business Strategy: 67%

Digital Readiness: 80%

Human-Centric Digitalisation: 100%

Data Governance 100%

Automation & Artificial Intelligence: 56%

Green Digitalisation: 85%

In Stage 0, the company demonstrated an advanced level of digitalisation, with particular strengths in the areas of data governance and human-centred digitalisation. There was a particular need to catch up in the areas of automation & artificial intelligence and digital business strategy.

DMA score and results – Stage 1

Digital maturity level: 80%

Digital Business Strategy: 67%

Digital Readiness: 80%

Human-Centric Digitalisation: 100%

Data Governance 100%

Automation & Artificial Intelligence: 48%

Green Digitalisation: 85%

The fact that the score in Stage 1 was not significantly better than in Stage 0 may be due to the fact that it was only through working with SAL as part of the EDIH Applied CPS that the company became aware of where there was potential for digitalisation, and therefore the self-assessment after service delivery was in some cases slightly lower.

Lessons learned

The collaboration between SAL and ETIKETA on the "test before invest" service proved to be very successful. The short project duration required a close partnership with the customer, and ETIKETA's quick response in providing samples, defining tests and discussing results demonstrated the effectiveness of this collaboration. This proactive approach facilitated the efficient progress of the service and enabled the identification of specific use-case relevant needs.

To enhance the overall process, it may be beneficial to consider an initial introduction to the subject matter for SMEs not actively involved in the requested research service. Investing time in understanding the topic in the early stages of the project could lead to more informed feedback and a better understanding of the results provided by the EDIH partner.

Other Information

"ADVANCED SMART TEXTILES: INTEGRATED PRINTED SENSORS THROUGH HEAT-PRESS TRANSFERS" at the International Exhibition and Conference for Flexible, Organic and Printed Electronics (LOPEC 2024) in Germany: LOPEC Poster Rauter.pdf

Need support?

Consult our catalogue to locate the Eupopean Digital Innovation Hub nearest to you and accelerate your company's digital transformation.