General details

EDIHs involved

Challenges

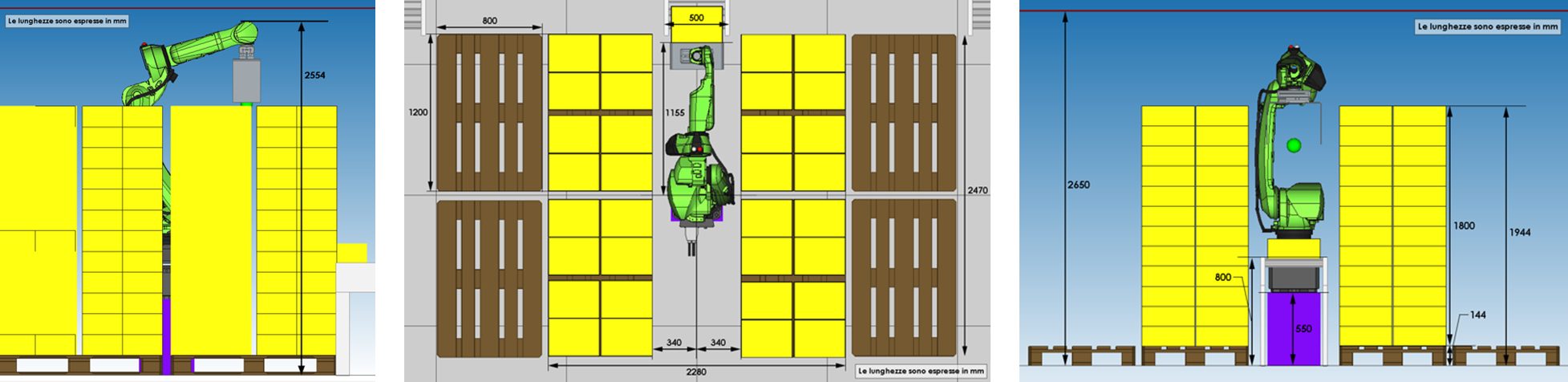

The goal of this project is to verify the feasibility of robotic palletising. The case study concerns the end-of-line process for a food sector company specializing in poultry distribution.

Currently, operators take boxes from a roller conveyor and manually palletize them onto four pallets arranged in a rectangular matrix downstream of the roller conveyor. Up to twelve boxes must be stacked vertically on each pallet.

The purpose of this study is to verify the possibility of automating the process while meeting the following requirements:

-

The automation must be able to handle two different logics:

-

Tight sequence palletising, where the boxes are stacked vertically, completing one column at a time;

-

Wide sequence palletising, where the boxes are arranged horizontally, completing one layer at a time;

-

-

The four pallets must be palletised simultaneously;

-

The gripping system must be able to handle boxes of different sizes and weights;

-

Cycle time: 400 boxes/hour;

-

Use of collaborative robots due to the lack of space for installing containment barriers and guards;

-

The space available for automation is very restricted due to the need to cool the environment:

-

length 2600 mm;

-

width 2600 mm;

-

height 2650 mm.

-

The project output is required to include:

-

The layout of the robotic station defining the model of collaborative robot;

-

The design of the gripping system;

-

The simulation of the application (necessary to verify the reachability of all points and to program the palletising logic);

-

The experimental validation of the solution through prototypes

Solutions

The "box-like" geometry of the boxes prevents the use of vacuum systems for gripping. Therefore, the gripping will be managed with a parallel gripper equipped with fingers thin enough to slip between boxes during palletising. The gripping system was designed with the support of SCHUNK Intec.

The main advantage of using pneumatic technology is the weight and cost savings compared to an electric device of the same size.

The PHL 40 has a variable closing force between 435 and 1,300 N, depending on the supply pressure, ranging from 2 to 8 bar. To increase the friction force, a layer of rubber was placed between the gripper fingers and the boxes.

To satisfy the requirements, the FANUC CR-35iB robot was selected: with an equal reach compared to other cobots, the CR 35 has a payload of up to 35 kg, which allows it to move two boxes without exceeding the load diagram limit.

The simulation, carried out with the Roboguide software, shows that the robot is capable of palletising up to 480 boxes per hour by picking up two boxes at a time from the roller conveyor. The highest point reached by the robot is 2,554 mm from the ground. Therefore, there is a margin of 96 mm between the robot and the ceiling.

The results of the simulations in terms of the number of boxes palletised per hour and the effectiveness of the gripping system were experimentally validated during tests conducted on a prototype of the robotic station. The entire automation process was recreated in the i-Labs Industry laboratory, replicating the layout studied in the simulation, including the arrangement of pallets and the roller conveyor. Regarding the gripping force, it was adjusted by varying the supply pressure of the gripper until achieving the optimal closing force, sufficient to maintain the grip during all phases of movement but not so high as to bend or damage the boxes. The tests also confirmed the simulation results in terms of reachability and the number of boxes palletised per hour.

Results and Benefits

Altesia operates as an innovation manager on behalf of major companies in the food industry, focusing particularly on logistics applications and the management of industrial processes.

Taking into account the constraints given by both customer and food industry, the research process followed for this EDIh4Marche service allowed the creation of a fully functional prototype. Collaborative robot FANUC CR-35iB robot, equipped with Schunk PHL-40 gripper, was at the heart of the automation process: the robot was programmed to pick up and palletise open boxes of varying sizes and weights on pallets in a condensed layout, while remaining below the ceiling level.

Tests performed at i-Labs Industry on the constructed robotic station showed, in fact, that the developed solution is capable of meeting the requirements in terms of space compactness, handling of open boxes, and cycle time. Moreover, challenges presented by the station logic were also overcome, with robot routines allowing flexibility in terms of palletising sequences. Such routines could be easily modified and adapted to meet eventual additional requirements.

The robotic station can therefore be proposed to producers and distributors of fresh foods in order to automate the palletisation of pallets, thereby increasing process efficiency and relieving human operators currently employed in this strenuous task. An increased efficiency, as well as productivity, while maintaining the product quality offered so far, can also be converted into lower labor costs and, consequently, increased profits.

Perceived social/economic impact

Adopting robotic palletizing technology offers significant improvements for companies in the food sector, both socially and economically:

-

Increased efficiency and productivity: the robotic system can handle up to 480 boxes per hour. This leads to faster processing, reduced bottlenecks, and improved throughput, enabling companies to meet customer demand more effectively without additional labor costs.

-

Reduced labor costs and enhanced resource allocation: automating palletizing reduces the need for manual labor in repetitive and strenuous tasks, cutting labor costs and allowing workers to focus on more strategic, value-added roles such as quality control and process improvement.

-

Improved workplace safety: robotics eliminate the need for manual heavy lifting, reducing the risk of injuries and promoting a safer work environment. This results in fewer workplace accidents and lower associated costs, such as medical expenses and compensation.

-

Better product handling and quality: advanced gripping technology minimizes product damage during handling, enhancing the quality of goods delivered and reducing waste and returns. This improves customer satisfaction and reduces costs associated with damaged products.

-

Flexibility and scalability: the system adapts easily to changes in packaging or pallet configurations, providing flexibility and scalability for future growth. This makes it a versatile investment that can evolve with business needs.

-

Energy efficiency and sustainability: robotic systems typically consume less energy than manual operations, contributing to sustainability goals and potentially reducing energy costs, which aligns with the industry's push for environmentally responsible practices.

-

Competitive advantage: embracing automation positions companies as leaders in innovation, enhancing their market competitiveness and potentially attracting new customers while also positioning them for future growth and industry leadership.

Measurable data

- Number of boxes palletised by the developed robotised station: 480 boxes per hour (higher than the cycle time followed by operators, i.e., 400 boxes per hour);

- Maximum height reached by the robot during palletisation: 2554 mm from ground (lower than the threshold imposed by the environment ceiling, i.e., 2650 mm);

- Maximum speed reached by the robot: 750 mm/s;

- Maximum box weight to be palletised: 15 Kg;

- Supply pressure for optimal box gripping: 4 bar;

- Reachability: guaranteed by the robot arm reach for all the boxes positions.

DMA score and results - Stage 0

The company has an average level of digital maturity, which indicates that it has started to integrate some digital technologies into its operations, but still has room for improvement. It currently uses common digital technologies, but could benefit from investments in more advanced and innovative solutions, such as information management systems, ERP and artificial intelligence. The digital skills of staff are adequate, but further training and support would be needed to meet the challenges of digital transformation and to improve preparedness for advanced technologies.

Lessons learned

What worked:

-

Simulation and testing: using roboguide for simulation was effective, allowing for performance optimization and accurate predictions. This approach ensured a smooth implementation and confirmed the system’s capabilities during testing.

-

Adaptable gripping system: the parallel gripper with adjustable pneumatic force and rubber layers managed various box sizes and weights effectively, ensuring reliable product handling.

-

Collaborative robotics: the fanuc cr-35ib was well-suited for the space constraints with its payload capacity and compact design, enabling safe, efficient operation without extensive safety barriers.

-

Efficiency gains: the system’s ability to handle up to 480 boxes per hour significantly boosted productivity, exceeding manual handling capabilities and meeting the cycle time requirements.

Challenges encountered:

-

Space constraints: limited installation space posed challenges. While the robot fit well, careful planning was required to accommodate all components and ensure efficient operation.

-

Gripping system complexity: adjusting the pneumatic gripper and rubber layers was complex. Accurate calibration was needed to avoid damaging boxes and to ensure consistent handling.

Recommendations for other companies:

-

Automate repetitive tasks: automation enhances efficiency and safety in high-volume, repetitive tasks, reducing labor costs.

-

Invest in simulation: thorough simulation and testing help identify issues early and optimize performance, preventing costly mistakes during implementation.

-

Evaluate space requirements: assess space carefully to avoid operational constraints and ensure effective installation.

-

Consider collaborative robots: ideal for limited space and close human interaction, collaborative robots offer flexibility and safety without extensive barriers.

-

Prepare for gripping system challenges: invest in calibrating and maintaining gripping systems to ensure reliable performance.

Advisability of adoption:

-

Yes, adoption is advisable

Need support?

Consult our catalogue to locate the Eupopean Digital Innovation Hub nearest to you and accelerate your company's digital transformation.